Microhardness and nanohardness meters of the NanoScan family have been developed

in FGBNU TISNUM since 1995.

For more than 20 years FGBNU TISNUM has been the leader of domestic analytical instrumentation in the field of physical and mechanical properties research

in FGBNU TISNUM since 1995.

For more than 20 years FGBNU TISNUM has been the leader of domestic analytical instrumentation in the field of physical and mechanical properties research

Microhardness

and nanohardness

testers «NanoScan»

"NanoScan" is more than 90 devices, including multifunctional measurement complexes, embedded measurement modules and standalone instruments

Microhardness and nanohardness meters of the NanoScan family are developed and manufactured at FGBNU TISNUM

Device modifications

Hardness testers are designed

and manufactured in Russia

and manufactured in Russia

Due to the modular principle, the configuration of microhardness testers and nanohardness testers can be individually customized

Modular principle

NanoScan implements more than 30 methods covering all main types of measurements of physical and mechanical properties

Measurement methods

We provide fast delivery of microhardness meters and nanohardness meters within 2 months

Fast delivery

devices

devices

Technical solutions applied

in the family of microhardness testers

NanoScan" family of microhardness and nano-hardness meters are protected by patents of the Russian Federation

in the family of microhardness testers

NanoScan" family of microhardness and nano-hardness meters are protected by patents of the Russian Federation

Patents

Vickers scales from HV 0.01 to HV 30

The device is registered in the State Register of Measuring Instruments

Construction of hardness distribution maps and profiles

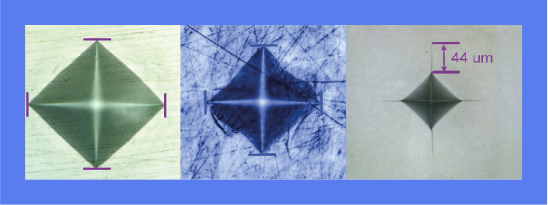

Automatic detection of print boundaries using machine vision algorithms

Wide range of lenses and filters. Motorized turret

Vickers hardness measurement according to GOST

Definition of K1C

Measurement of hardening layers and coatings, heterogeneous materials

Automated application of arrays of prints

Micro-hardness tester NanoScan-HV - automated device for Vickers hardness measurements in accordance with GOST R ISO 6507-1-2007

Any questions?

Contact us

Contact us

Vickers microhardness tester NanoScan-HV

NanoScan family scanning nano-hardness testers

Areas of application

Principle

Scanning nano-hardness testers of NanoScan series are intended for investigation of the surface topography, elastic modulus mapping and for measuring the mechanical properties (including hardness and elastic modulus) of bulk materials and thin films on a submicron and nanometer scale.

The unique features of NanoScan allows using the devices in applications where investigations can be carried out with traditional nanoindenters and SPMs and also in the areas inaccessible for such equipment. Scanning nanohardness testers of NanoScan series are used for surface mechanical properties investigations and quality control in the following applications:

- Nanophase and composite materials;

- Superdispersed hard alloys;

- New superhard materials;

- Nanoconstructional materials;

- Semiconductor technology;

- Automotive industry;

- Engineering applications;

- Medical applications;

- Diamond and diamond powders;

- Memory storage devices;

- Optical components;

- Micro- and nano- electromechanical systems(MEMS and NEMS);

- Thin films;

- Friction reducing coatings.

NanoScan technology is based on principles of scanning probe microscopy (SPM). The main characteristic feature of NanoScan is the use of piezoceramic probe sensor with high bending stiffness of the cantilever (~2 Х 104 N/m).

The use of the regime of resonance oscillations allows to perform the tracking of contact between the probe tip and the surface on two parameters: change of amplitude and frequency of the cantilever oscillations. This makes it possible to separate the viscous and elastic components of the tip-surface interaction, and distinguish an elastic surface and a viscous contamination layer on it, as well as to measure the mechanical properties of the surface.

High bending stiffness of the cantilever permits to go through the viscous layer until the contact with rigid surface and to make a modification of surface (indentation and scratching). The probe design allows to use diamond indentors of different type. The listed functional capabilities give a great distinction between NanoScan and other nanoindenters and SPMs.

The use of the regime of resonance oscillations allows to perform the tracking of contact between the probe tip and the surface on two parameters: change of amplitude and frequency of the cantilever oscillations. This makes it possible to separate the viscous and elastic components of the tip-surface interaction, and distinguish an elastic surface and a viscous contamination layer on it, as well as to measure the mechanical properties of the surface.

High bending stiffness of the cantilever permits to go through the viscous layer until the contact with rigid surface and to make a modification of surface (indentation and scratching). The probe design allows to use diamond indentors of different type. The listed functional capabilities give a great distinction between NanoScan and other nanoindenters and SPMs.

All the measurements are made in the open air without any special vacuum or thermal sample preparation. All the original technical decisions applied in NanoScan are protected by the copyright laws of the Russian Federation.

© 2023 Scanning nanohardness,

microhardness testers NanoScan

microhardness testers NanoScan